At Vivienne Westwood, one of our main goals is building a strong and transparent supply chain. This includes being accountable for the working conditions under which our products are manufactured in order to guarantee the safety and wellbeing of the people working with us and our products, directly and indirectly. A direct supplier is a supplier who provides goods or services directly to us, without any middlemen. An indirect supplier can be a middle-man or a supplier of a supplier (sub-supplier), such as a material supplier who sources raw materials like cotton for garment production.

Since we brought our manufacturing and sourcing back in-house to be managed directly by Vivienne Westwood in 2019, we have been strengthening our supply chain monitoring programme every year.

We have a dedicated team both in London, UK and Milan, Italy looking after our supply chains.

Our auditing programme, initiated in 2019 by our Milan hub and extended to our UK-managed supply chain in 2022, aims at measuring and monitoring the risk of, amongst others, modern slavery, employment standards and environmental risks in our supply chain.

This first phase of our auditing programme focuses on key direct manufacturing suppliers. These include all the key supply chain partners the Company directly conducts business with. We define ‘key’ to mean suppliers with highest order quantities, in locations of high risk and those we have a long-standing relationship with.

The announced audits assess workplace conditions of the factories, and they are conducted by our partnering consultants. We are able to consider and evaluate audit reports provided by our suppliers, in line with the main social and environmental international audit standards (like SEDEX SMETA and SA8000).

Our onsite audits assessments cover several areas such as:

| Labour Conditions | Wages and working hours |

|---|---|

| Facility regulations or employee handbooks; employment contracts; union or employee representative committee procedure/record; collective bargaining agreement; employee records and personal files; Foreign employees work permits and approval letter from the government; agency worker agreements; , hygiene and healthy workplaces, gender equality and parental leaves. | Payroll records of the last 12 months; time card/attendance records and production records; local minimum wage standard; Wages/working hour policy/procedure and related training records; employee’s social insurances receipts. |

| Health and safety | Management systems |

| Legal permits and licenses; building safety and stability; light, noise and temperature; fire equipment and emergency plans/emergency drills; PPA and other protection systems; chemical hazard and related risk management. | Written social compliance policy and relevant procedures and records and related training records; Environmental management systems. |

| Environmental standards | |

| Environmental management programme and procedures; certificates; hazardous waste disposal records environmental certificates and permits; use of renewable energy; preventative measures against spillages; preventative measures against discharge of hazardous substances in the environment. |

Our supply chain is managed by our two main offices: 25% of our supply chain is managed through the London headquarters - Vivienne Westwood LTD, while the remaining 75% is managed by our Milan-based offices - Vivienne Westwood SRL.

We have 100% visibility of our direct manufacturing suppliers (Tier 1) of both Italy-managed and UK-managed supply chains.

By 2022, 75% of our direct manufacturing suppliers, those who we have a direct relationship with through our Milan hub, have been audited by a nominated second party at least once since the commencement of our auditing programme.The majority of our key direct manufacturing suppliers managed through our Italian arm are located in Italy, followed by Turkey, Portugal, Tunisia and Kenya.

The majority of UK-managed key suppliers are located in Thailand and the UK, with one manufacturer located in Hong Kong. Our audit programme has been extended to this UK-managed supply chain in 2022 and so far we have audited 80% of key direct manufacturing suppliers.

Our audits have resulted in only occasional non-compliances. These have been addressed through corrective action, which we monitor seasonally. Severe non-compliances require verification audits onsite, and repeated audit failures can result in the termination of our partnership with suppliers. Willingness to receive audits and remediate non-compliances is part of our contractual agreement with suppliers.

With every season, our audit programme is expanding to also include sub-suppliers and the fabric and material manufacturing tiers of our supply chain. We have a documented procedure to collect information regarding sub-suppliers involved in the manufacturing of our products. Our direct manufacturing suppliers are requested to share the complete list of sub-suppliers they are collaborating with, and update this list with each new season. To formalise and further commit to supply chain traceability, we developed a sub-supplier policy, which has been implemented starting from 2023 by both our Milan hub and the London headquarters. This document will help us increase transparency regarding direct manufacturing suppliers that sub-contract any or part of their services, relative to the production activities they have externalised and to provide improved visibility on sub-suppliers within our supply chain.

Modern Slavery is defined as exploitation of an individual by others, for personal or commercial gain. This means a person loses their freedom, whether they are tricked, coerced, or forced. This includes but is not limited to human trafficking, forced labour and debt bondage.

As a UK based Group, we recognise and align with the UK Modern Slavery Act 2015.

In 2019, we launched our Modern Slavery suite of documents, which includes our Modern Slavery Policy, our Code of Labour Practice and Business Conduct, Whistleblowing Policy and Tool, and a Due Diligence Questionnaire.

Our Whistleblowing Policy lists examples of concerns or suspicion of wrongdoing, unethical practices or criminal acts that can be reported to us. It also provides a whistleblowing report form that individuals forming part of our supply chain can complete and explains how we will respond to any concern or incident reported to us.

In 2022, our Italian operating company has substituted the offline physical paper document with a new advanced online Whistleblowing tool to modernise the process, in which our Italian suppliers now have access through a QR code that leads to the main page of the software to proceed with any reporting.

All direct suppliers are required to formally comply with the above mentioned standards. We will start extending these policies to our core service providers from 2023 onwards. Read more here.

We welcome steps by the UK government to encourage more effective action on Modern Slavery by introducing changes to the Modern Slavery Act 2015, which may include further responsibilities for companies like ours. In addition, we welcome the European Commission’s proposal for a ban on producing and importing goods made using forced labour, and other relevant legislations expected to come into force in the near future.

In 2019 VW SRL joined the UNECE’s Sustainability Pledge, which consists of a series of policy recommendations, guidelines and standards for traceability and transparency, that enable industry actors to authenticate their sustainability claims. Find out more here.

From 2019 to 2021, within the Sustainability Pledge’s framework, VW SRL participated in the ‘Traceability and Transparency pilot project for the Cotton Value Chain’, supporting in the validation and testing of the methodological standard for the supply chain data collection.

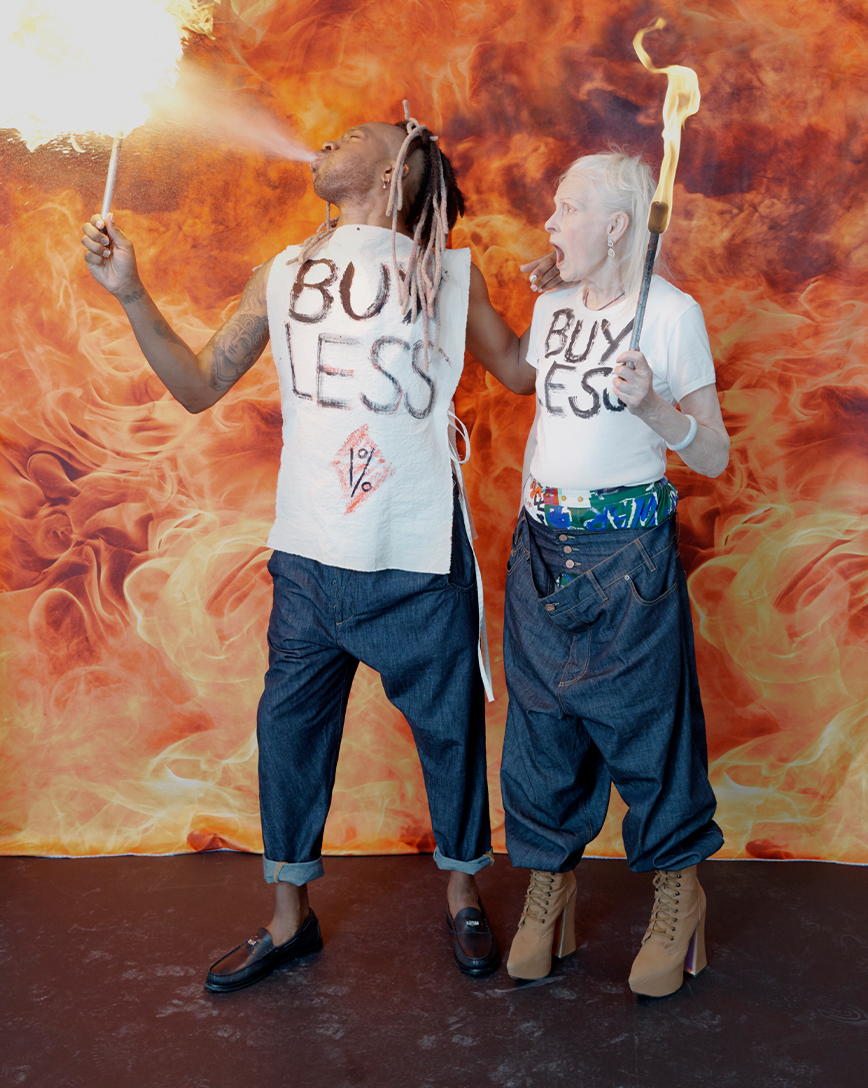

The project was meant to trace in a transparent manner all the supply chain phases of the product from the distribution up until the upstream sourcing level of the cotton fibre. We applied this to two of our garments, an organic cotton t-shirt and a pair of denim jeans made of blended recycled cotton yarn and virgin cotton.

As a conclusion, this project allowed us to validate a methodological standard for data collection for traceability and transparency through a strategic collaboration with supply chain partners.

We are currently testing different tools and methods to extend traceability across our supply chains and products, which include the implementation of LCAs (Life Cycle Assessments). Traceability is one of our main development areas and a key goal for the advancement of our sustainability strategy.

Read more here on the Sustainability Pledge.

Read more here about UNECE and their mission.